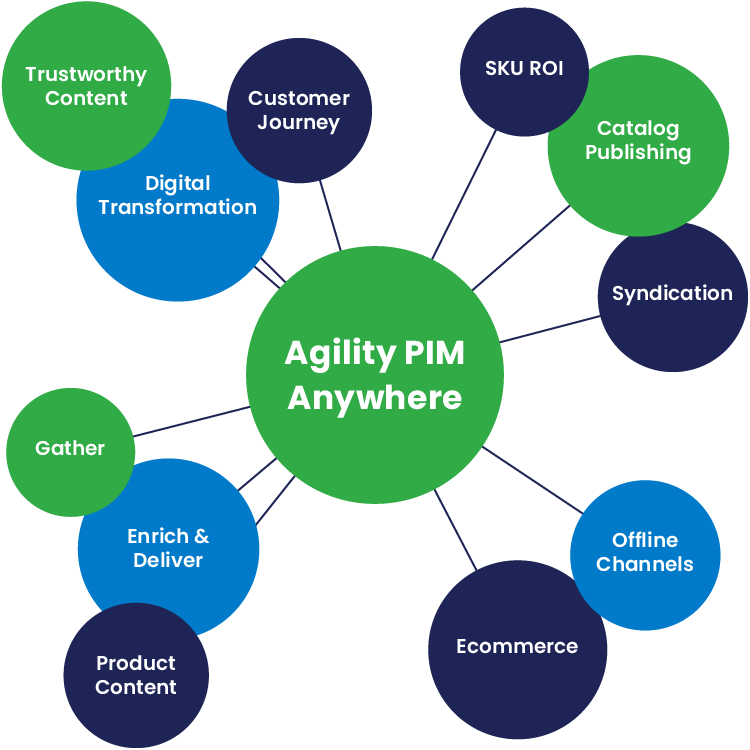

Get Products to Market Faster

with an easy-to-use, comprehensive Product Information Management Solution that simplifies supporting commerce across digital and traditional channels.

Is Your Product Data Making You Money or Costing You Sales?

Are Your Products and Services Not Being Found by Your Target Customers?

Product information that is incomplete, out of date or not enriched won’t show up in competitive searches or won't be found on your eCommerce site. Managing product information manually across channels leads to missed opportunities.

Is Onboarding New Products or Supplier Data Taking You Too Much Time?

Products need to appear on virtual shelves right away to make sales, If onboarding long supplier lists, or making quick changes to product listings is taking too long, customers will find the product somewhere else. You need to understand a product’s completeness for all channels and to automate approval and syndication the instant it’s ready

Wasting Time Dealing with Antiquated Systems without Seeing Productivity Gains?

Are your manual or last-gen systems not allowing your team to collaborate in real time? Is your product content decentralized requiring team members to scramble to update information across disparate systems?

Trusted By

Enhance Data Quality

In the face of constantly changing regulations and legal requirements, maintaining compliance with industry mandates and global laws is challenging. Agility PIM helps you address issues and eliminate incomplete attribution, inconsistent attribute values and uncontrolled choices. Control consistency with choice lists and inherited values. Trust our strong data integration capabilities to detect, correct and quarantine unwanted content on import.

Align Channels

Create a single repository of product data for multichannel publishing to ensure your customers will encounter impeccable consistency, no matter where they look. Agility PIM provides your team with a centralized entry point for managing all your product data while simultaneously making it simple to select the exact output you need to meet the differing data requirements, governance rule and hierarchies of your various output channels.

Boost Performance

Good PIM isn’t just about data, it’s about maximizing the productivity of your team while improving their satisfaction with their work. With Agility PIM you will reduce redundancy, rework, and repetition, and ensures you’re no longer beholden to error-prone, complex spreadsheets. Streamline your market launch activities and keep everything moving from one step to the next with task lists and notifications. Maintain your product content in a single, trustworthy source so you can spend less time search for the latest update and more time focused on increasing your market reach and boosting overall performance of your team

Effectively Manage Your Product Information – No Matter The Industry

Our Expertise

Whether you have one website or a dozen, support two languages or twenty, or manage thousands of product attributes or millions, Agility PIM flexibly scales to empower users across a variety of industries with a single, reliable view of their product information.

From merchants and product managers, content managers and copy writers, marketers and eCommerce managers, to translators, and IT – Agility PIM helps all enterprise stakeholders meet the challenge of the age of distributed commerce.

Distribution

Our customers in the distribution industry manage mid-sized, large, and extremely large product portfolios – tens or hundreds of thousands to millions – with extraordinary numbers of attributes. Most of them need to produce multiple versions of marketing content and pricing schemes for a great many commercial channels, including eCommerce, catalogs, and the field sales team.

Learn how Agility PIM helps distributors differentiate themselves and gain competitive advantage against other companies selling the same products.

Manufacturing & Global Brands

As a manufacturer, you might manage a narrower scope of products, but often with the added complexity of a global footprint. Commerce and marketing campaigns tend to be country specific, with all of the versioning and localization complexity that entails, including multiple language translations for every channel.

Learn how Agility PIM helps manufacturers harness the many layers and levels of value within product data to extend and uphold a recognizable brand that translates effectively across borders and throughout the supply chain.

Retail

Whether you have thousands or hundreds of thousands of products, it’s critical to deliver product information and rich content that’s not just trustworthy but complementary.

Learn how Agility PIM helps retailers increase sales, foster customer loyalty, and create a consistently exceptional experience across all of your customer touch points, whether online, in store or mail order.

Are you Ready for PIM?

Our 3-minute PIM Readiness Assessment can show you the potential value a PIM solution can bring to your company.

SKUs from 4,500 suppliers

100% elimination of duplicitous entries

Agility is a fantastic product, with a great team of people behind it.

Speak to an Expert